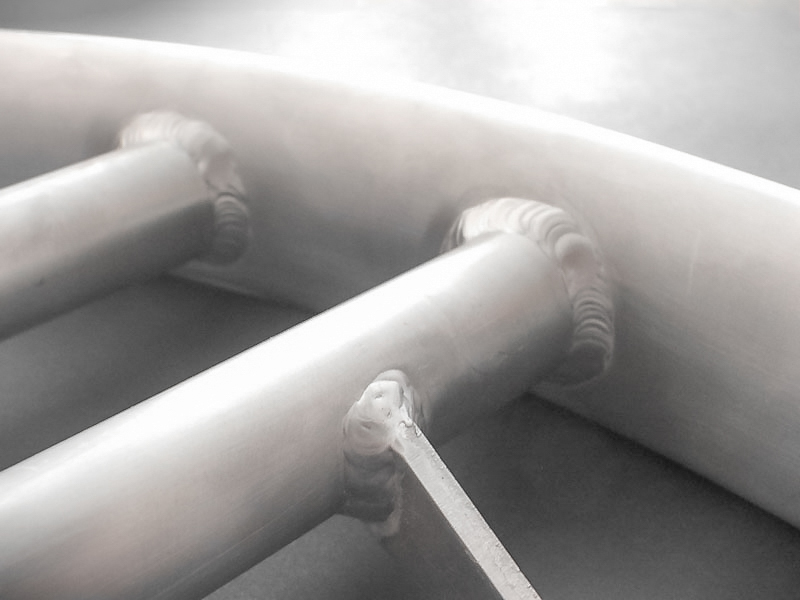

Aluminium welding

Since its foundation, our company has also included aluminium welding among its services. An International Welding Engineer (IWE) supervises the welding process. Our credentials are confirmed by the 15085 certification for class CL2 as well as EN ISO 3834. We offer not only aluminium profile welding, but also the welding of aluminium sheets and pipes. We are able to fabricate complete welded aluminium structures based on a Client's documentation. This includes both large structures from bent pipes as well as thin walled elements. Our welders are qualified according to EN ISO 9606-1/-2, which guarantees the quality of the services undertaken. We invite you to place your request for welded aluminium components and in return can offer professional technical advisory and efficient execution of all projects.

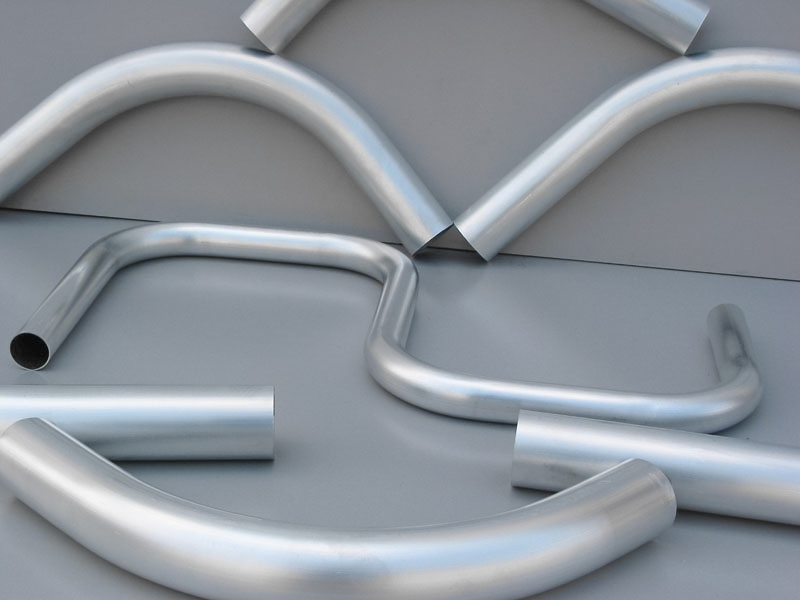

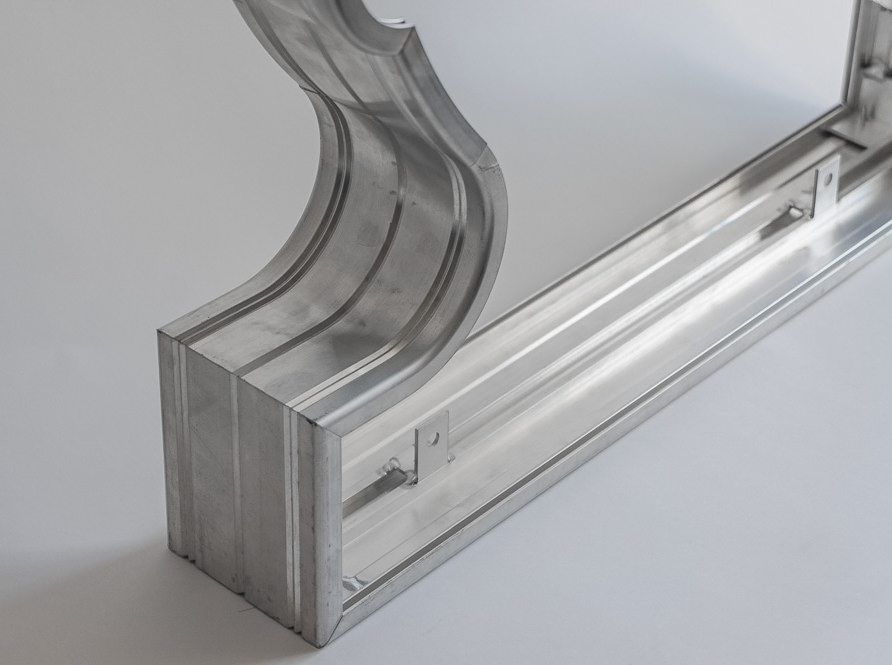

Aluminium bending

The range of treatments offered by Copal includes the bending of aluminium profiles. We offer not only bending using rolls and presses, but also MANDREL bening. Having our own machine shop gives us access to the dedicated tools needed for bending profiles requested by Clients. The maximum radius we can obtain when tension bending is R=650mm. Our offer includes bending non-standard profiles with non-standard radii and alloys. Thanks to our own ageing furnace, we can also offer hardening, which is the ageing of aluminium profiles after bending, to hardness condition T4. We offer our clients complete repeatability, achieved by maintaining 100% control of the production process. We also offer additional working of bent profiles, including welding, CNC machining, and punching. Our company provides machining services both on aluminium profiles delivered to us and on materials purchased by us according to Client specifications.

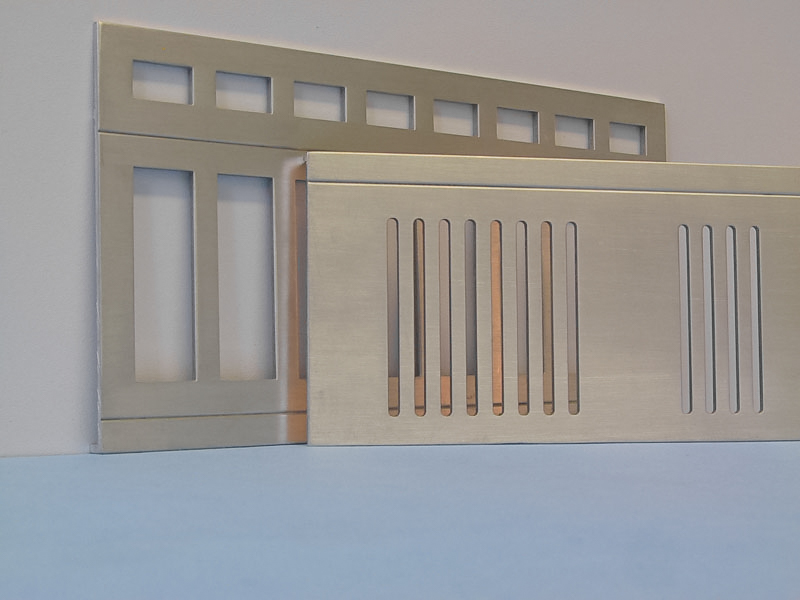

Punching

Copal has also offered punching among its services since its inception. In cases of batch production this solution guarantees low production cost, while maintaining high repeatability. We own eccentric and hydraulic presses with pressures of up to 64 tonnes. Our long running cooperation with a provider of punching tools allows us to undertake projects from the very beginning. Our clients may have complete trust in our knowledge and experience in the field of punching. We prepare comprehensive production lines in order to minimise costs and increase production efficiency.

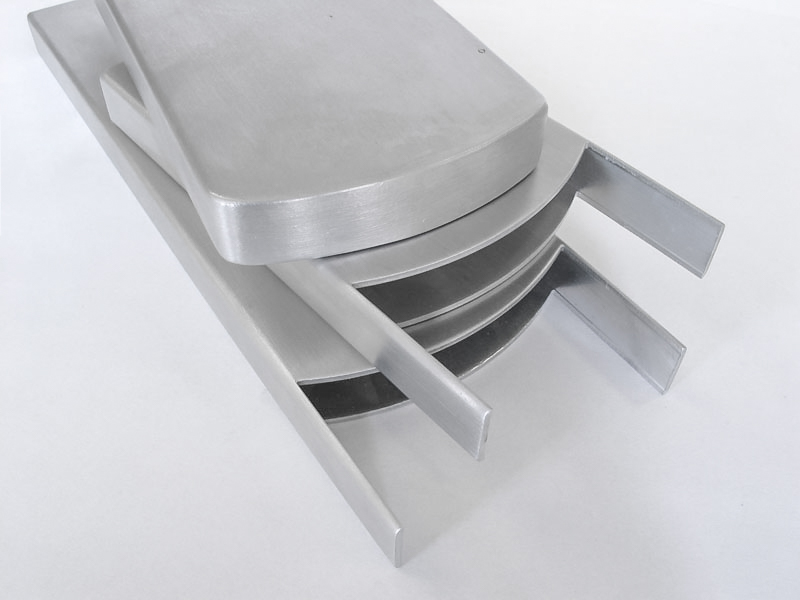

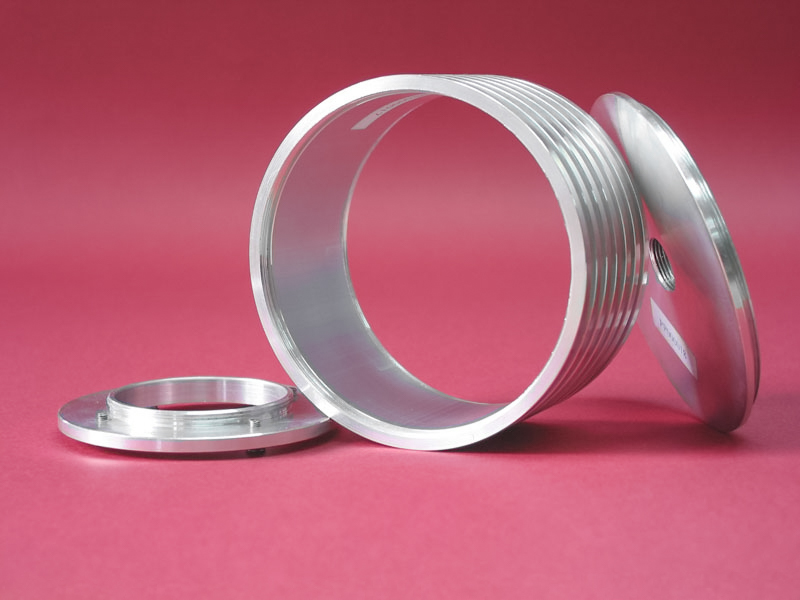

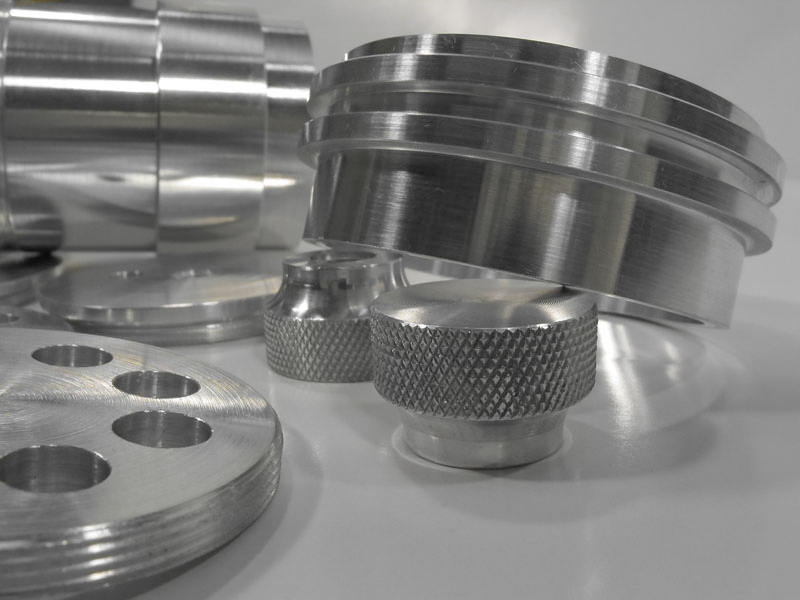

Machining

Our services include the turning and milling of aluminium profiles. Our constantly improved machinery allows us to perform milling within a very narrow scope of tolerances and with high requirements regarding surface classes. Our trained staff prepare deployment and measurement documentation as per our Client’s requests. All products are controlled during production, and production documentation is stored in order to guarantee the highest quality of service to our Clients. We are constantly upgrading our machinery, which allows us, for instance, to offer the milling of sheets and plates. A milling plotter with a work surface of 6x2.2 m also allows us to mill 6m profiles. We make all our own milling tools, which allows us to fully control the process and effectively react to any changes. We also provide decorative machining services, used, for instance, in the furniture industry.

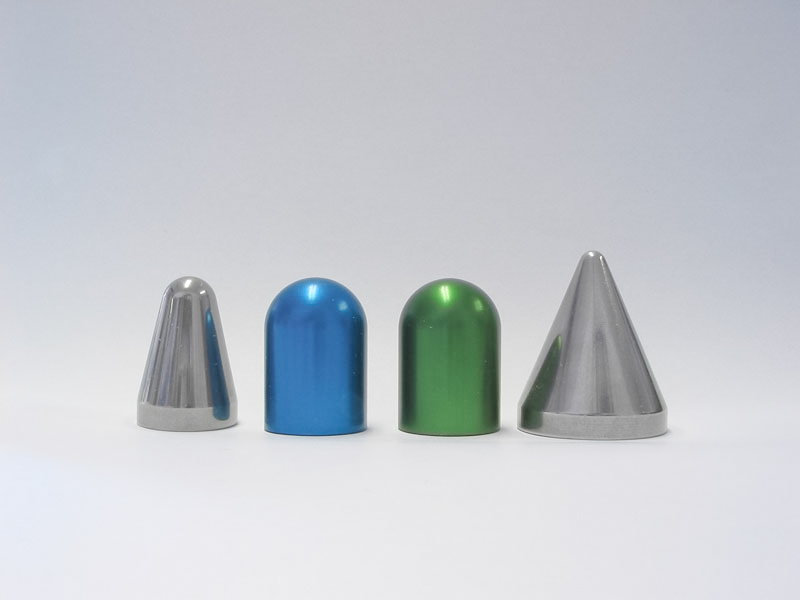

Finishing

In the case of products that require finishing after treatment, we also offer a full range of surface treatments of aluminium details in accordance with Client specifications. The scope of services we offer includes:

- standard, natural and colour anodising , as well as hard anodising

- powder and electrophoretic coating acc. to colour palettes Ral, Dekoral, Ncs,

- sanding and glass bead blasting

- mechanic polishing

- brushing surfaces

These services are performed by our proven and trusted subcontractors, guaranteeing the highest quality of service.

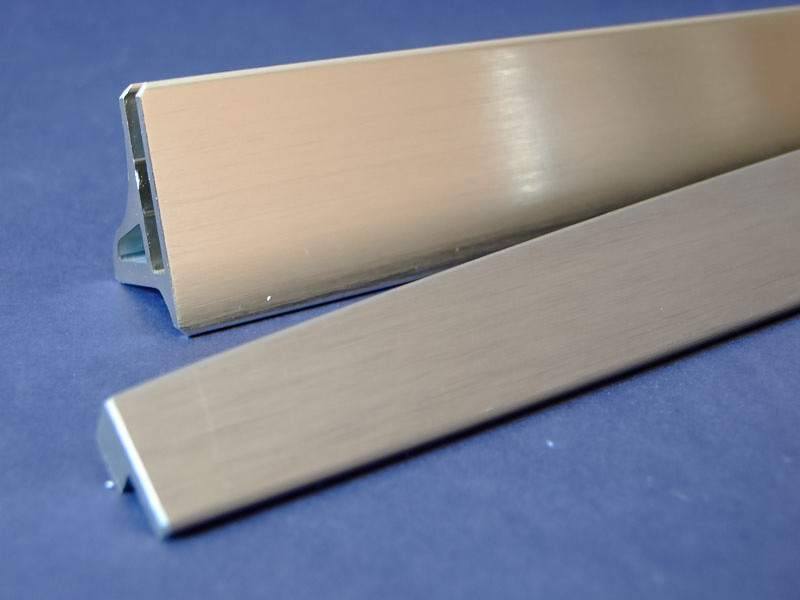

Aluminium lightbox frames

In addition to the general fabrication of aluminium profiles, we also specialize in the production of advertisement panel brackets and bending of Aluminium lightbox frames. We make frames in the form of:

- circles

- ovals

- rectangles

- rectangles with rounded corners

- other shapes, customised to the individual needs of the client

- Bent corners for the manufacture of panels as well as lighting handles and supports make our range of products complete.

NON-STANDARD ORDERS ARE OUR SPECIALTY