News

Production optimization

21.08.2017

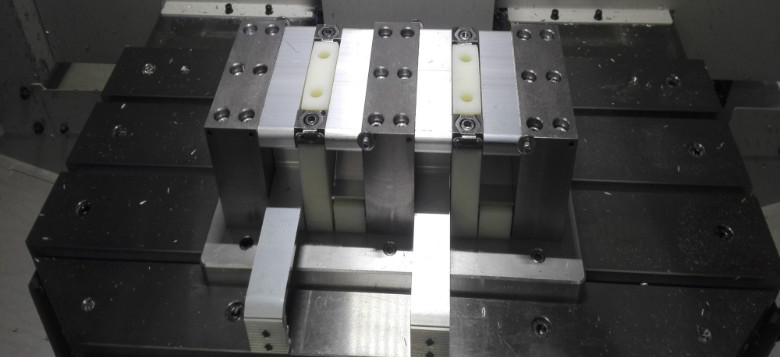

Our customers pay increasing attention to the price pressure generated by the market, while we are constantly obliged to seek solutions that reduce production costs. Our team of engineers responsible for implementing and optimising the production processes, together with our customers design solutions to eliminate changeover times to maximise machine uptime. An important aspect of these activities is optimising the fasteners and programmes for the CNC machine tools.

By participating in trade fairs and external training, we help to continually grow our knowledge levels. We focus on optimisation, on matching the production technology to the size and frequency of the production batches, and on shortening the material flow times within the company.

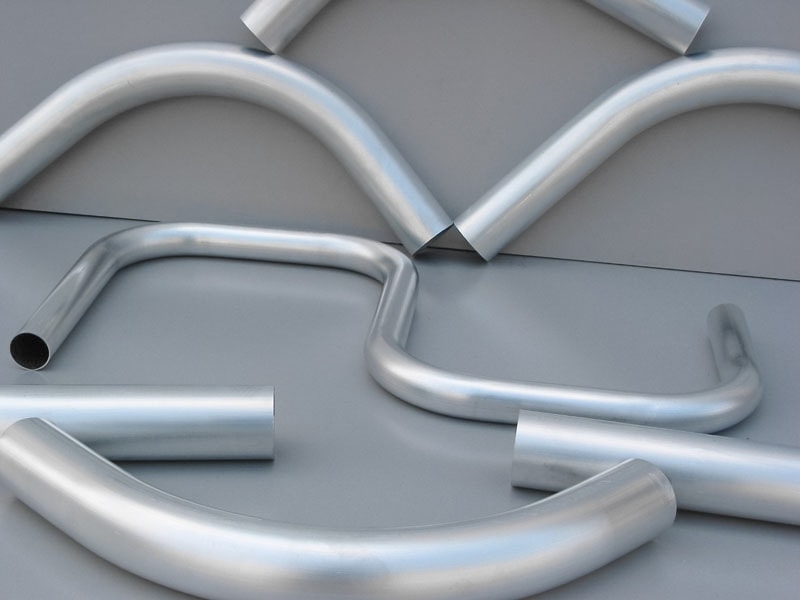

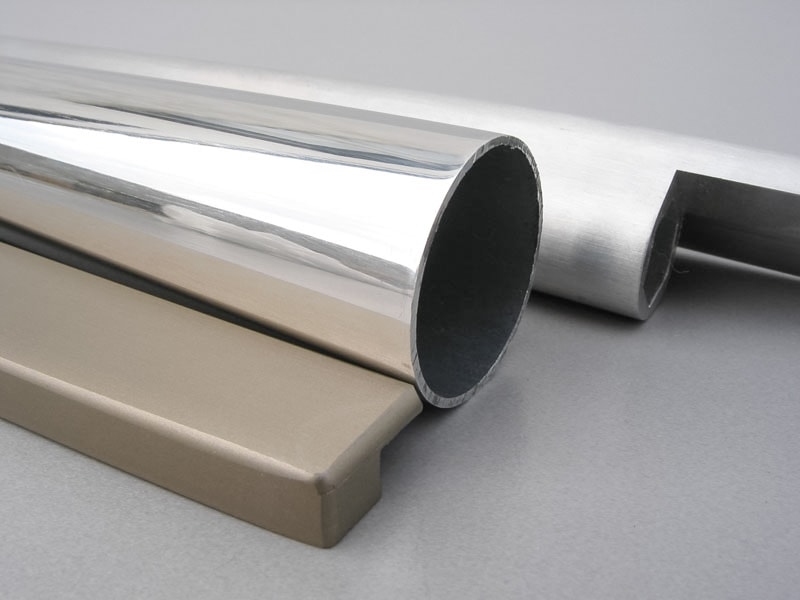

AGEING FURNACE – SUPPLEMENT FOR THE OFFER IN BENDING ALUMINIUM PROFILES

In our attempt to meet the expectations of our partners, in addition to a series of various bending machines, our own tool-room and 20 years of experience in profile bending, we have supplemented our offer with aluminium profile ageing and ageing details after bending. If we are dealing with difficult aluminium bending, these are often T4 profiles that are the source material for bending (naturally aged). They lack full mechanical strength and it is then necessary to harden profiles (age them) to T6.

Copal is one of the few companies that has its own ageing furnace that supplements our offer in bending aluminium profiles.

Added 05.01.2017 by Wojciech Brzozowiec

Our aim is to shorten deadlines!

Our aim is to shorten deadlines!

Our aim is to shorten deadlines!Our company now boasts additional new CNC machines produced by KIMLA

Added 28 Oct 2015 by Wojciech Brzozowiec

TIG and MIG welding of structures

We offer welding of structures of various sizes using TIG and MIG techniques, from small ones, made of thin walled materials, up to large-scale, thick walled structures.

Added 26 Nov 2014 by Wojciech Brzozowiec

non-standard projects

Added 25 Nov 2014 by Wojciech Brzozowiec

gold medal of sub-junior championship, UKS KAJAK team trzcianka

A snapshot of the achievements of competitors we currently support. A gold medal at the sub-junior championship, UKS Kajak team Trzcianka Bydgoszcz 2013 - race K-4/500 m.

A snapshot of the achievements of competitors we currently support. A gold medal at the sub-junior championship, UKS Kajak team Trzcianka Bydgoszcz 2013 - race K-4/500 m.Added 24 Nov 2014 by Wojciech Brzozowiec

Obróbka aluminium na Facebook

Added 21 May 2014 by Wojciech Brzozowiec

kimla plotter

The latest addition to our machinery, a KIMLA gate milling plotter with a work area of 6100 x 2200

The latest addition to our machinery, a KIMLA gate milling plotter with a work area of 6100 x 2200This gives us the ability to machine composite panels and details up to a height of 350mm. The plotter has a negative pressure table and works on four axes. We also have a full staff of trained operators. We invite you to contact us in order to learn more about the possibilities offered by the plotter.

Added 08 May 2014 by Wojciech Brzozowiec

we have certificates inEN ISO 3834-2 and DIN EN 15085-2

We are pleased to inform you that on 20 March 2012, a certification audit took place within our company and from that date onwards, the Copal has the right to use certificates:

DIN EN ISO 3834-2 Quality requirement for the fusion welding of metallic materials. Comprehensive quality requirements.

DIN EN 15085-2 Welding of railway vehicles and components. Quality requirements in class CI2 The audit was carried out by GSI SLC certification agency.

| Welding process | Material group | Dimensions | Comments |

| 141 | 23 | 1-4mm | FW |

| 141 | 23 | 1,5-6mm | BW |

| 141 | 23 | 1,5-4mm | FW |

| 141 | 23 | 1,4-2,6mm | BW |

| 141 | 23 | 3-8mm | BW |

Added 18 Feb 2014 by Wojciech Brzozowiec